Close

Osmosis is the phenomenon of water molecules passing through a semi-permeable membrane from a region with lower dissolved solids to a region with higher dissolved solids until a near equilibrium is reached. Reverse Osmosis (RO) is a membrane process of purification which removes most of the total dissolved solids (TDS) in water by reversing the natural process of osmosis. Pressure is applied to a TDS-concentrated solution against a semi-permeable membrane, causing pure water to diffuse through the membrane. RO has become an important process for a wide variety of applications including: medical, laboratory, desalination, industrial wastewater, Deionized (Dl) pretreatment, and drinking water.

Electrical conductivity is the most convenient method for testing RO water quality and membrane performance. Pure water is actually a poor electrical conductor. The amount of ionized substances (salts, acids, or bases) dissolved in water determines its conductivity. Normally, the vast majority of the dissolved minerals in tap, surface or ground water are conductive impurities. Myron L® Company has conducted extensive research relating conductivity to TDS, resulting in instrumentation and calibration solutions which have become the standard of the RO industry.

When calibrating your conductivity instrument for testing fresh water, the “442 Natural Water Standard™” solutions are the best choice. These solutions are available in various concentrations. 442 solutions contain the following salts diluted in pure water: 40% sodium bicarbonate, 40% sodium sulfate and 20% sodium chloride. These are the most common salt compounds in surface and ground water. A sodium chloride solution provides better results in brackish or sea water because the predominant salt in these waters is sodium chloride.

ORP (Oxidation Reduction Potential/REDOX) and pH are important parameters in measuring the success and useful life of an RO membrane. The ORP may be used to determine the activity of an oxidizer. RO membranes are susceptible to attack by oxidizers such as chlorine, bromine, ozone and hydrogen peroxide. The activity of the oxidizer is more informative than the chemical residual because it determines the ability and speed of oxidation. A high ORP reading would indicate a need for pretreatment. A low ORP may indicate biological activity which may cause fouling of the membranes.

ORP can also be used to determine an overfeed of sodium bisulfite, which is used to reduce chlorine. If the ORP reading is under 200 mV, you have a reducing condition. This overfeed costs extra money and can lead to environmental discharge problems. It is best to check the reject water, where the concentration is highest. This will show even minute quantities of oxidizers or reducers.

pH is very useful in predicting membrane life and the scaling potential of feedwater. The higher the pH and calcium, the more likely it is that scale will form on the membranes. However, with silicon based compounds, a low pH will increase the tendency for scaling. Membranes also have a pH range where operation is optimal. It is often useful to check the pH of the reject water to help determine scaling potential.

Since 1963, Myron L® has manufactured single and multiple range handheld instruments. Model RO-1 and RO-1NC are reliable, single range instruments used to demonstrate the RO process to a prospective buyer. The color coding of the model RO-1 dial dramatizes the difference between high TDS (red-above EPA recommended limits for drinking water), medium TDS (orange – within EPA recommended standards for drinking water), and low TDS RO water (blue-high purity water). Installers prefer the three range 532 models or TechPro II™ TP1 or TPH1 because they are ideal for accurately testing both feed and product water.

Larger RO systems such as those found in bottled water plants, hospitals, industrial process, or seawater desalination require continuous monitoring to verify water quality and membrane condition. For continuous measurement of water quality, Myron L® manufactures a variety in-line monitor/controllers.

The 900 Series Multi-Parameter Monitor/Controller™ models simultaneously monitor and/or control multiple inputs/outputs. Input parameters include conductivity, resistivity, TDS, salinity, pH, ORP, flow/pulse and temperature. The Percent Rejection function of the 900 Series is designed to help quantify the effectiveness of water filtration systems. This is accomplished by comparing the feed water to the permeate (product) water to determine the percent of dissolved solids removed or rejected by the filtration system. The RS- 485 serial output allows you to download data to a supervisory computer, PLC or SCADA system.

The 720 and 750 Series II Monitor/controller models are available for individual parameters.

All Myron L® controller models contain heavy-duty relay(s) with adjustable set point(s) which can be used to activate alarms, valves, autodialers, etc. A variety of options and outputs are available to cost-effectively tailor the monitor to the particular RO application.

The Ultrameter™ 9PTKB, 6PIIFCE and 4PII are preferred by water treatment professionals for calibrating and checking Commercial/industrial RO systems. They appreciate the waterproof case, ability to store and record 100 memory data records, and 3 pre-programmed solution curves. Ultrameters are compact, but their multiple parameters give them the versatility of several instruments.

Myron L® also manufactures single parameter pens for dip or scoop sampling. The Ultrapen™ PT1 or PTBT1 deliver stable, lab-accurate readings of Conductivity, TDS, Salinity and Temperature. The PT2 or PTBT2 (pH and Temperature) and PT3 or PTBT3 (ORP and Temperature) pens are also available for spot checks and pretreatment screening. All Ultrapens are waterproof, durable, and easy to use with one-button functioning.

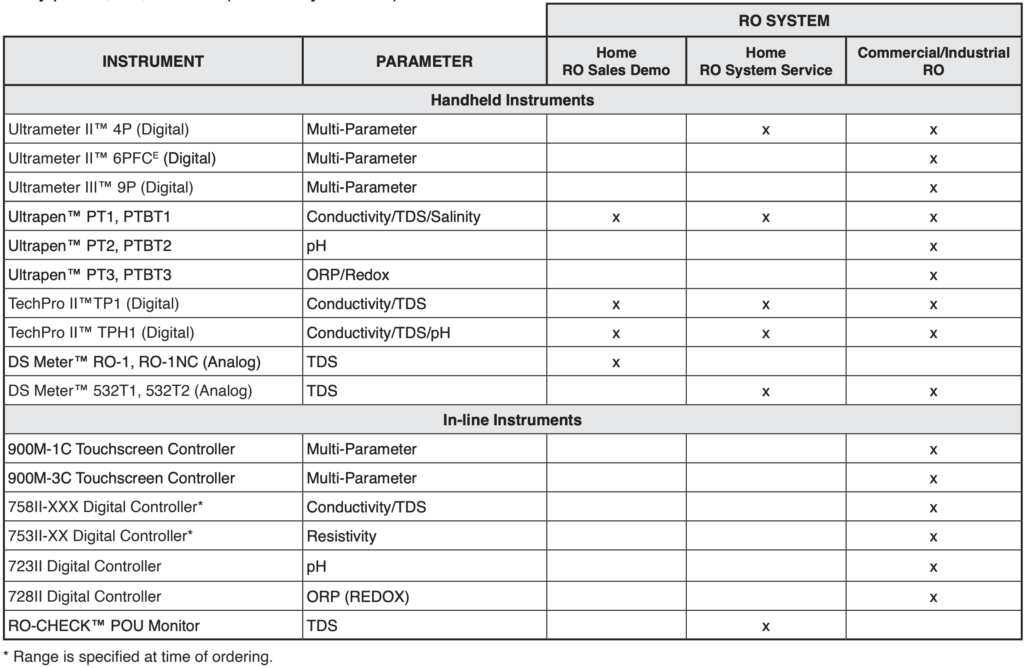

The following table briefly covers some of the Myron L® Company instruments recommended for RO Systems. For further details, please contact your local distributor, refer to Myron L® data sheets, visit our website (www.myronl.com), or contact us by phone, fax, or email ([email protected]).