Close

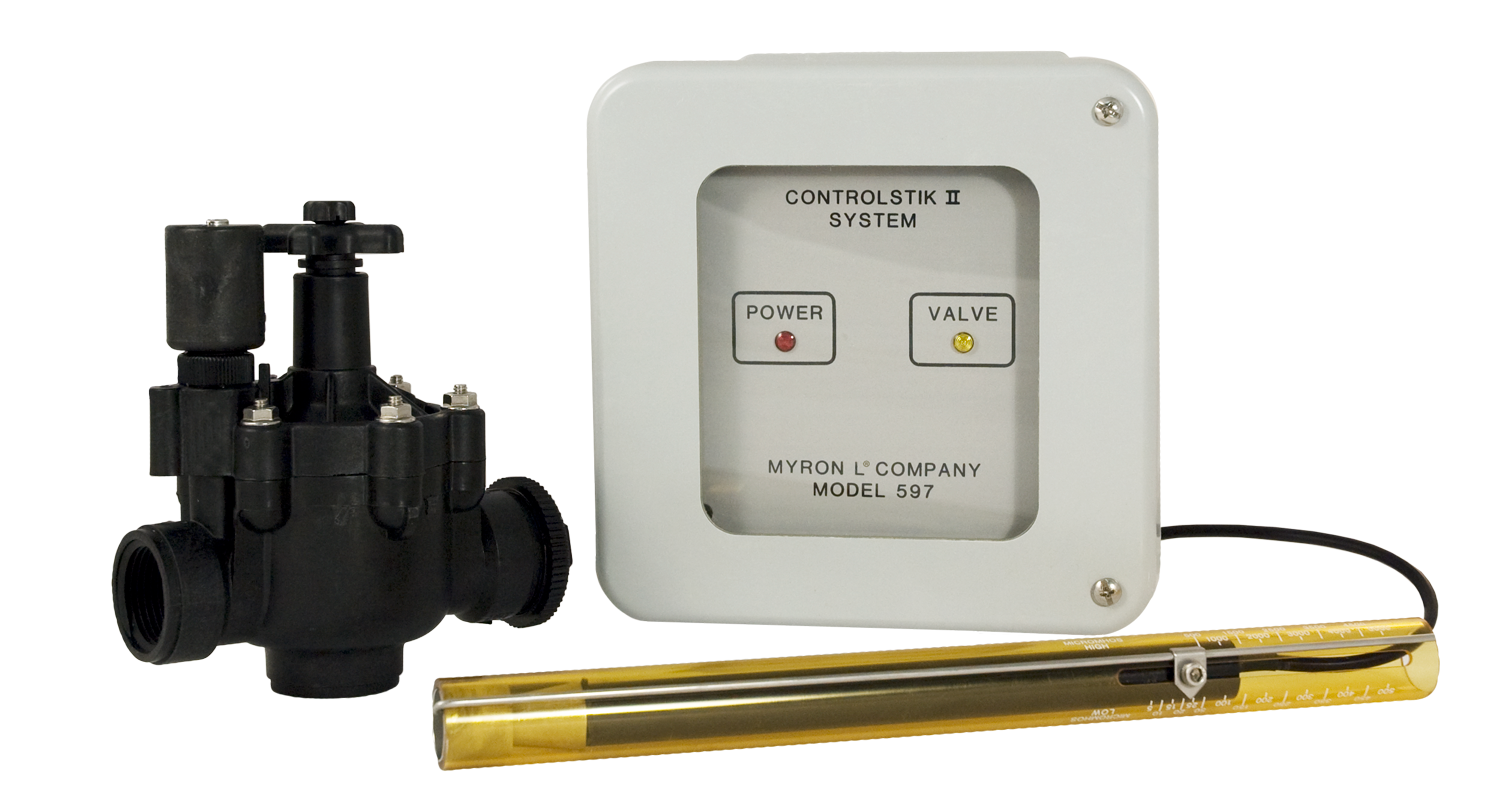

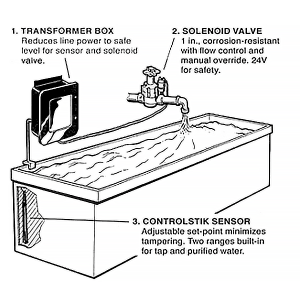

The Myron L® CONTROLSTIK II™ Rinse Tank System dramatically reduces the amount of water used in continuous flow rinse tanks. At the same time, it automatically maintains optimum water purity, ensuring effective rinsing.

The three parts of the CONTROLSTIK II System are easily installed. The CONTROLSTIK II (conductivity sensor) is set at a tolerable contamination level and submerged in the tank. Water cannot flow into the tank until drag-in from rinsed parts causes the contamination level in the tank to rise above the pre-set point. The CONTROLSTIK II (sensor) then signals the solenoid valve to open, adding fresh water. As soon as this fresh water dilutes the contamination to the tolerable pre-set level, the CONTROLSTIK II (sensor) closes the valve.

Rinse water usage shall be minimized by means of automatic conductivity control systems. They shall consist of a temperature compensated conductivity sensor, corrosion resistant one-inch solenoid valve, and transformer box which safely reduces line power to the sensor. Enclosure shall be fiberglass with heavy rubber gasket and 316 stainless steel. Circuitry shall be solid-state, and unaffected by changes in voltage. Setpoint adjustment shall be on sensor to minimize tampering. Rinse tank controls shall be Myron L Model 597 or approved equal.

| Input Power | Choice of 110 or 220 VAC, 50/60 Hz; |

| Automatic voltage regulation insures operation of the systems from 105-125V or 210-250V respectively. | |

| Output | 24 volts @ 600 mA AC |

| Maximum Power Consumption | @ 117V: 12 watts (103 milliamps) |

| Enclosure | IP65/NEMA 4X fiberglass case with heavy gasket and 316 stainless steel hardware. |

| Lights | LEDs indicate POWER (red) and VALVE (yellow) |

| Electrical Installation | Either HARDWIRE with 5/8 in. conduit; or PLUG-IN with 8 ft./2,4 meter, 18 ga. 3-conductor plug. |

| (supplied with 110V systems only) | |

| Mounting | Flange on enclosure for easy wall mounting |

| Dimensions | 184 H x 197 W x 127 D mm/ 7.25 H x 7.75 W x 5 D in. |

| Ranges | 5-500 micromhos (for high quality water) |

| 500-5000 micromhos (for normal tap water) | |

| Power | 1 volt AC (from transformer box) |

| On-Off Span | Approximately 5% of setpoint |

| Temperature Compensation | Automatic to 25°C/77°F up to 82°C/180°F |

| Materials | Epoxy and 316 stainless steel |

| Cable | 10 ft./3 meter 22 ga., 4-conductor, vinyl jacketed |

| Installation | Corrosion-proof ABS bracket supplied |

| Dimensions | 304 L x 25 Dia. mm/12 L x 1 Dia. in. |

| Size | 1 in. NPT normally closed; compatible with plastic or metal piping |

| Power | 24 volts @ 200 mA AC |

| (from transformer box) | |

| Materials | Body: glass reinforced nylon |

| Diaphragm: nylon reinforced BUNA N synthetic rubber | |

| All exposed metal: stainless steel | |

| Operating Pressure | 10-100 psi / 0,69-6,90 bar |

| Miscellaneous | adjustable flow control |

| manual override | |

| anti-hammer closing | |

| conduit connector |